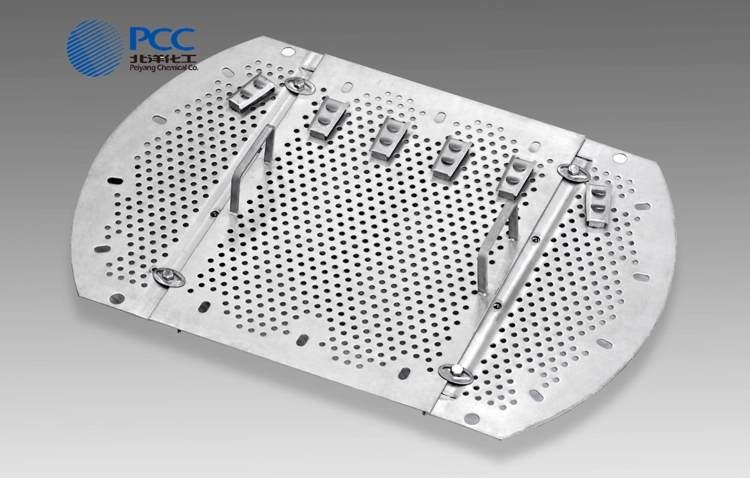

Trays provide uniform vapor and liquid flow with huge contact between the two phases. This will maximize mass transfer rate and permit the tower to achieve the separation. The proper selection of trays will ensure that the desired reacting is achieved.

Application of Tray

1. Widely used in basic chemical column;

2. Fine chemical filed like ethyl benzene / styrene, fatty acids processing plant;

3. Petrochemical field, used in oil refinery towers and gas processing plant like vacuum distillation tower, absorption tower, stripper, and natural gas dehydration tower.

Advantage of Tray

1.Widely used in distillation column, patent product of PCC.

2.Stable and efficient, provide large contact between phases, reduce energy consumption.

3.Low pressure drop, which leads to reduce energy consumption largely

4.Large flexibility, easy to be installed and overhauled

5.Customized for each type of liquid tray and requirement.

Type of Tray

|

Type

|

Name

|

|

|

Sieve tray

|

|

|

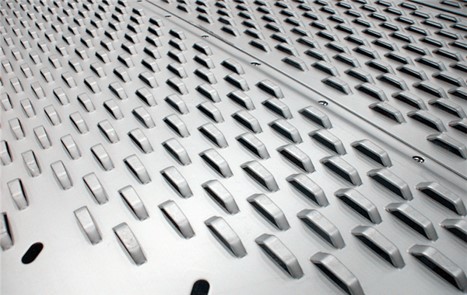

Guide trapezoid valve tray

|

|

|

Fixed valve tray

|

|

|

Vertical tray

|

Common Material of Tray

Stainless steel like304 (L), 316(L), carbon steel, Ti, 321, etc.

Common Package of Tray

1. wooden case 2.pack as demand